The Story of Plastic Armour

During WWII, the need arose for a form of armoured protection made from non-strategic materials which could be put into wide service. Captain Terrell, a peacetime barrister working in an Admiralty research department, made extensive experiments and eventually developed a formula consisting of graded chips of Penlee granite bound together by a mixture of small amounts of chalk and bitumen.

The armour could be poured in situ or made into plates backed by steel sheet, and was fitted to many ships and utility vehicles, such as mobile airfield defence guns. Any desired thickness could be provided.

At the end of the war, the civilan company that Terrell had commissioned to produce the armour tried to claim credit for its invention. Terrell won the case and was awarded a prize by the Admiralty for having developed it.

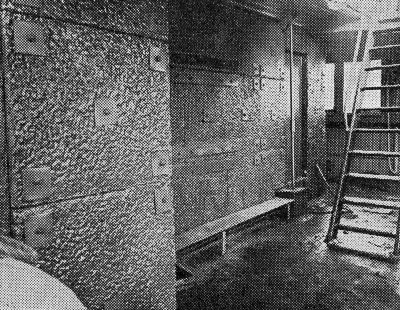

Armour installed on a ship

Plastic armour installed on the superstructure of a ship. This would be backed by sheet steel. Note the fixing bolts and flanges. |  |

|

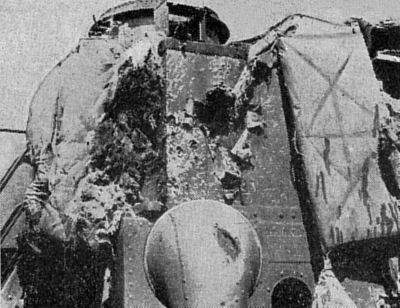

Plastic Armour does its jobA ship returning from a scrap with its plastic armour damaged by enemy fire. The armour absorbed the impact of the shells, the underlying superstructure receiving less damage as a result. No casualties were taken. |

© Copyright 2007 CairdPublications.com | Site Map | Contact Us |